COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Successful Conclusion of Kunming Changshui International Airport Terminal 2 Project Observation & Seismic Isolation, Energy Dissipation & Vibration Control Technology Exchange

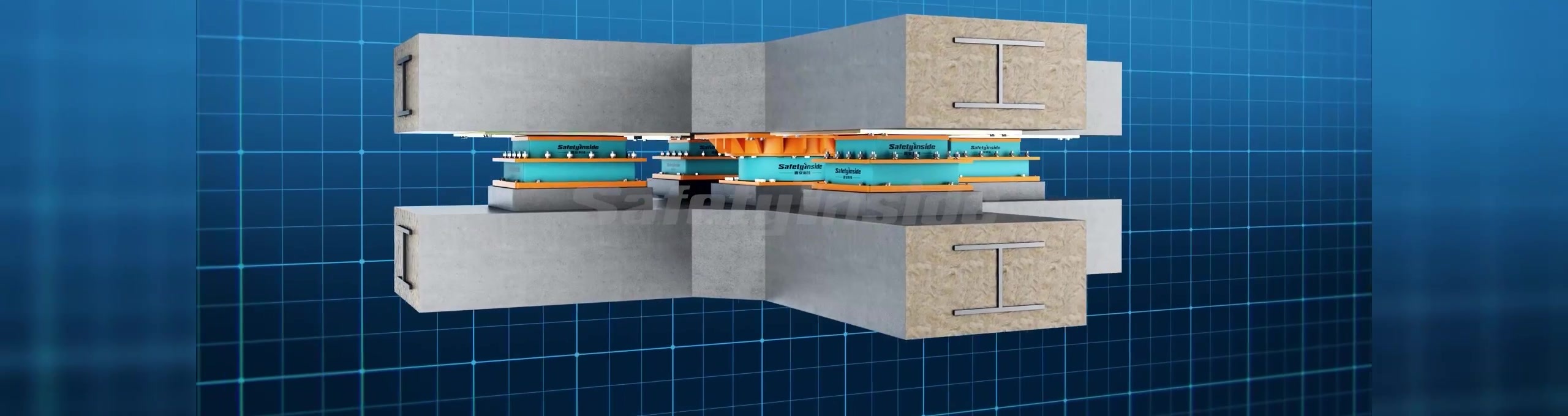

- The isolation layer utilizes lead-core rubber bearings (with diameters ranging from 1200mm to 1600mm), ordinary rubber bearings, and elastic sliding bearings. For the roof area above the high-speed railway tunnel, specialized seismic-vibration dual-control bearings are adopted, supplemented by viscous dampers to regulate the displacement of the isolation layer.

- To control the seismic displacement difference of isolation layers at different elevations, the stiffness of the first-floor structure has been enhanced: shear walls are partially installed, and column sections are enlarged.

- In response to the risk of excessive isolation layer displacement under extremely rare earthquakes, dual displacement control measures are in place: U-shaped special metal deceleration and limiting devices reduce structural movement speed via a stiffness mutation mechanism; meanwhile, metal folding damping buffers are mounted on the building’s outer walls to effectively absorb energy from potential collisions.

- For the high-speed railway’s main line area: a combined bearing system is used, integrating a steel spring unit (with an isolation frequency of 4Hz) in series with a horizontally slidable spherical hinge.

- For the arrival and departure line area: another combined bearing system is adopted, pairing a horizontal limiting high-elasticity unit (with an isolation frequency of 5.5Hz) in series with a horizontal rubber isolation unit.

Previous:

Innovative Tech, Benefiting All

To Be The World Leader In Seismic Isolation and Energy Dissipation

Copyright@Quakesafe Technologies Co.,Ltd.

Website construction:www.300.cn丨kunming

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home