LNG

Introduction to LNG Project

With the adjustment of the global energy structure, the demand for natural gas as a clean and efficient energy source is constantly increasing. As the main storage and transportation form of natural gas, LNG's storage tank construction demand will also increase accordingly, which provides a broad market space for the application of seismic isolation technology in LNG storage tanks.

The application of seismic isolation technology in LNG facilities is of great significance. It can improve the safety of facilities, ensure operational stability, and also have significant economic benefits.

In China, more than half of the LNG storage tank projects are provided with seismic isolation solutions by SAFETYINSIDE. On August 30, 2024, SAFETYINSIDE completed the construction of the world's largest single-tank capacity liquefied natural gas storage tank group - China National Offshore Oil Corporation Jinwan "Green Energy Port" Phase II project, marking the completion of the largest natural gas storage and transportation base in southern China, which will greatly enhance the natural gas supply guarantee capability of the Guangdong Hong Kong Macao Greater Bay Area and southern China.

The second phase of the Jinwan "Green Energy Port" project is located on a mountain facing sea, with a large number of complex terrain such as gullies, funnels, and easily loose weathered rocks. The area has high seismic forces and seismic fortification levels, making it one of the largest liquefied natural gas storage tank projects in the world with the most complex geological conditions and the most difficult seismic design.

These LNG storage tanks are over 60 meters tall and nearly 100 meters in diameter, and can stack up to three large passenger planes at the same time, with a capacity of 270000 cubic meters. It can release 169 million cubic meters of natural gas, which can reduce carbon dioxide emissions by 200000 tons compared to coal with the same calorific value, equivalent to planting 560000 trees. The liquefied natural gas in the storage tank is kept at minus 162 degrees Celsius, and a comprehensive refrigeration system ensures that the daily evaporation rate of liquefied natural gas is less than 4.5%, with insulation capabilities comparable to rocket fuel tanks. Six storage tanks use about 10000 pieces of low-temperature steel, with a total weight of nearly 20000 tons, equivalent to the total steel consumption of the "Bird's Nest" venue of the Beijing Olympics.

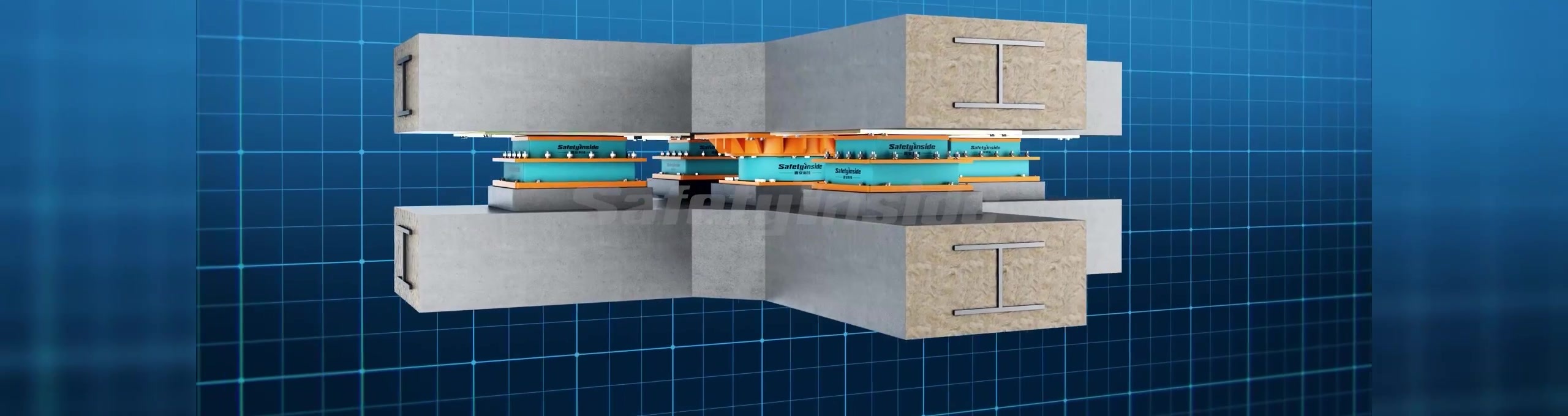

To break through the capacity limitations of storage tanks and enhance their safety and stability against multiple extreme working conditions such as earthquakes, more than 400 seismic isolation rubber bearings have been customized at the bottom of each storage tank to form a seismic isolation layer. When an earthquake strikes, the vibration energy of the lower foundation is first transmitted to the isolation rubber bearings. Through the deformation of the rubber under stress, most of the earthquake energy is buffered and reduced, effectively "isolating" the transmission of earthquake energy to the upper storage tank structure, thus achieving the effect of "using softness to overcome rigidity".